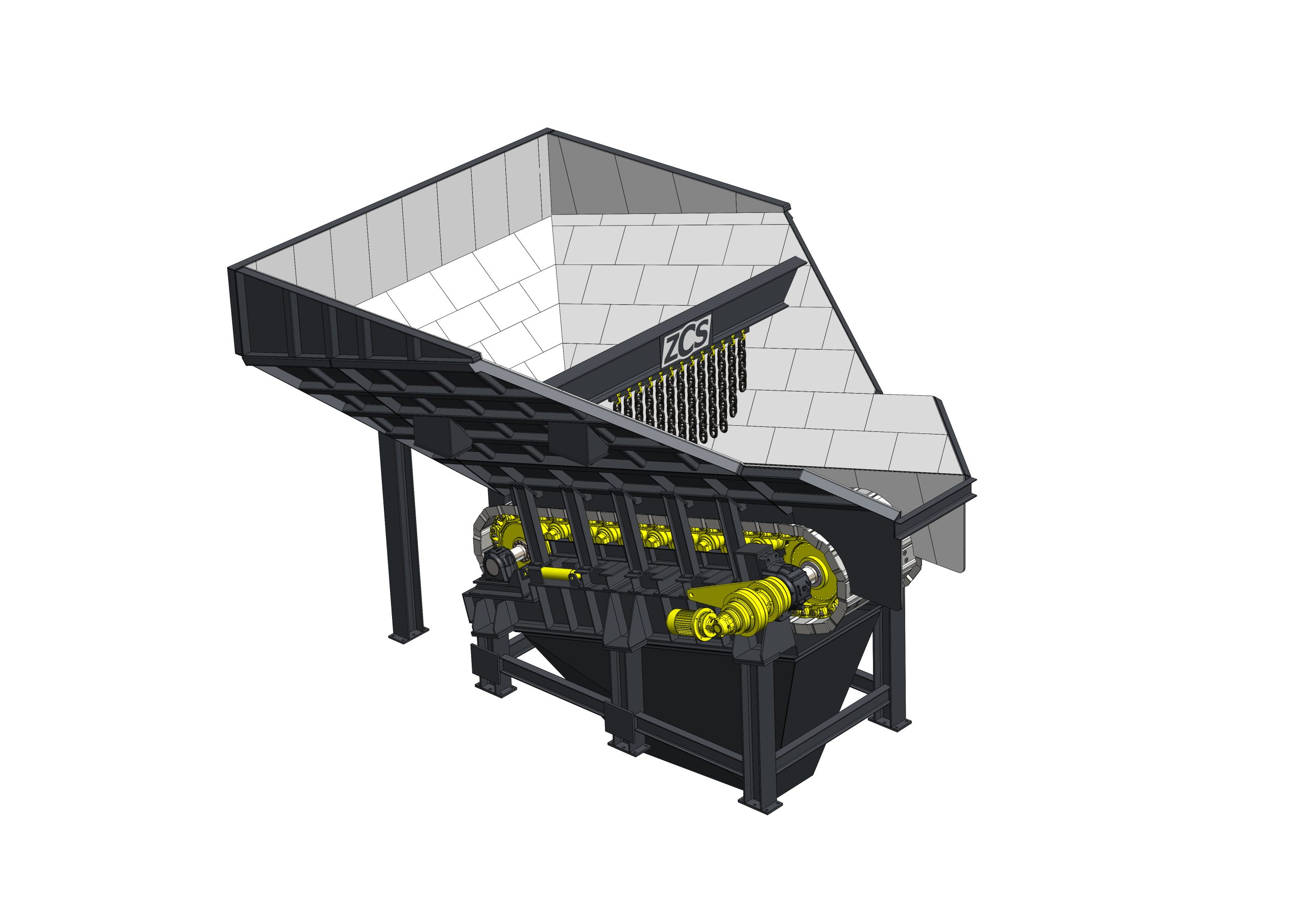

VULCANIZATION OF CONVEYOR BELTS

Our ZCS SERVIS service performs:

- vulcanization of conveyor belts by cold or hot method;

- repair of longitudinal and transverse cracks, both by vulcanization and mechanical connections;

- repair of sides.

Description

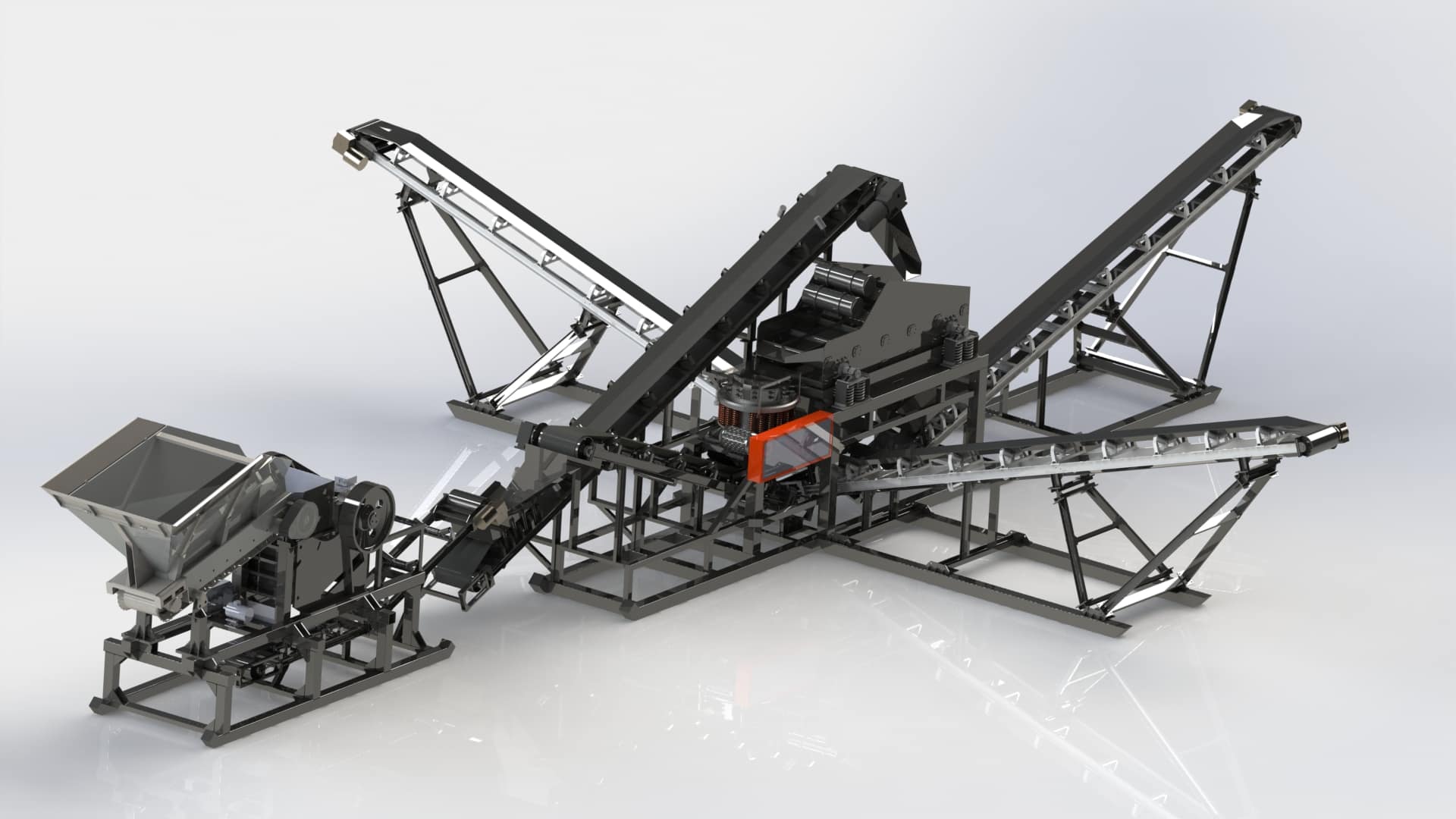

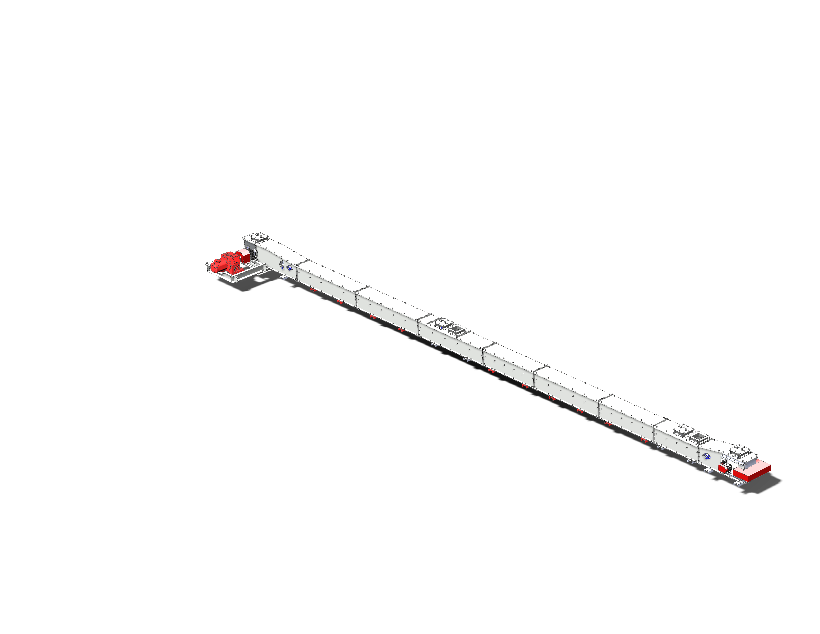

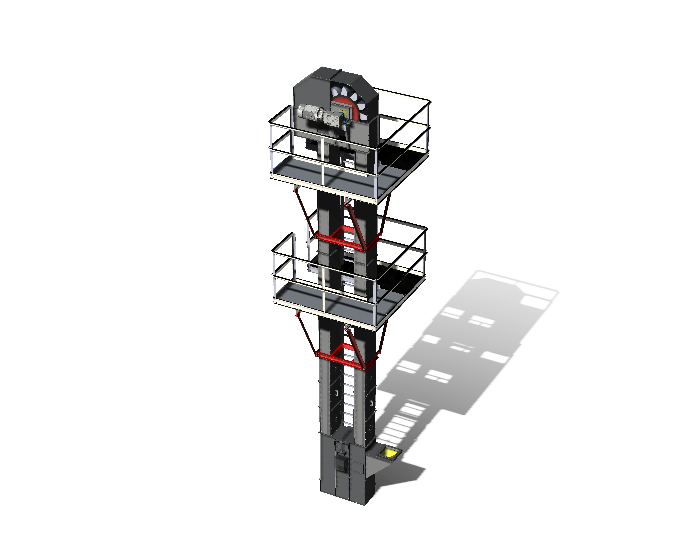

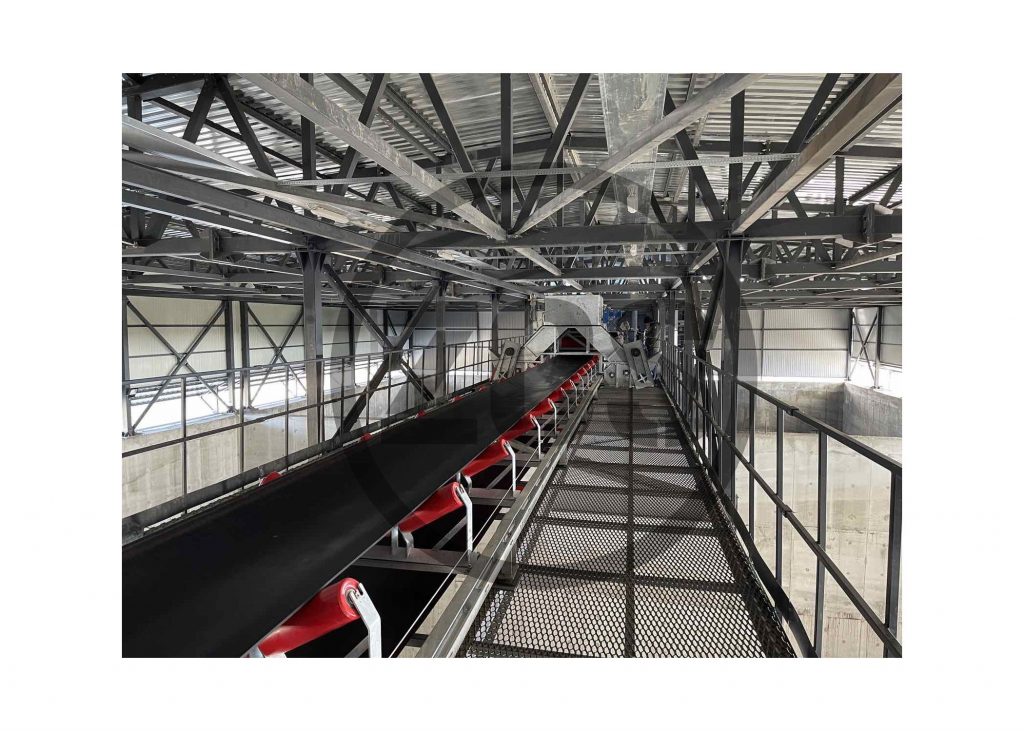

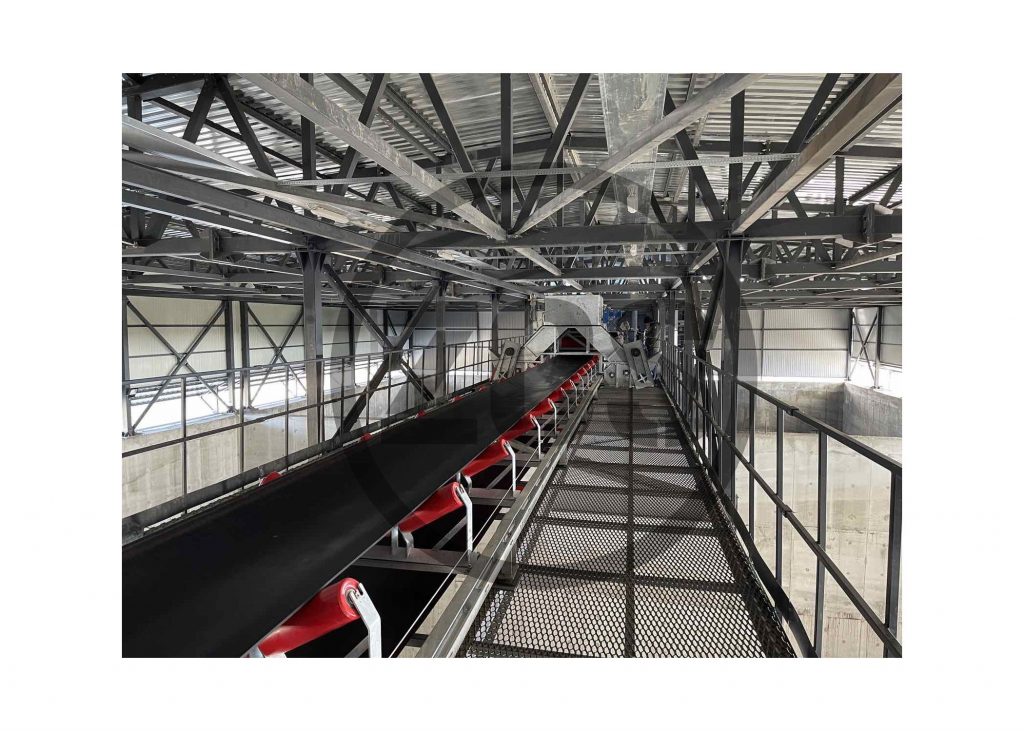

The efficiency of the operation of conveyor transport at enterprises of the mining, metallurgical, chemical industries, in the extraction and production of building materials, at enterprises of the food industry and in other spheres of economic activity largely depends on the quality of the conveyor belt and on how correctly the conveyor belt is connected before entering into operation

More than 60% of conveyor downtimes are related to the manufacture and repair of butt joints of conveyor belts. According to the majority of experts, the most reliable and durable joint of the conveyor belt is the method of hot vulcanization, and the service life of such a joint is comparable to the service life of the belt itself. Over the long years of our work, we have come to the conclusion that the joining of the conveyor belt can be done in three most effective ways:

Hot vulcanization

Cold vulcanization

Mechanical connection

If the conveyor belt is joined by one of the above methods, the strength of the joint directly depends on:

Qualifications of the personnel performing the work

Compliance with the work schedule when cutting the ends of the tape and assembling the joint

The quality of the materials used in docking

The connection of conveyor belts is an important component of the production process for the manufacture and repair of canvases. The efficiency of operation of the equipment directly depends on the strength of the joint seams, which is why special attention is paid to this issue. Experience shows that the majority of breakdowns of conveyors and conveyors are connected precisely with breaks in conveyor belts, as the most heavily loaded elements, therefore one of the most important tasks of the manufacturer is to ensure the maximum durability and reliability of the canvas.

In production practice, splicing of conveyor belts is carried out in three ways, which have proven themselves to be the most productive means of splicing — hot vulcanization, cold vulcanization, and mechanical splicing. Each of the technologies has specific features, so the selection of the optimal connection of the rubber fabric fabric is carried out based on the functional purpose and operating conditions of the conveyor. In general, the quality of a seam made by any of the mentioned methods consists of such important components as the professionalism of specialists, the exact observance of technologies and the use of quality materials.

Joining conveyor belts using hot vulcanization technology involves heating the web at the joint. The edges of the products are split and carefully smeared with glue, after which they are joined butt and boiled in a press. The advantage of hot vulcanization lies in the formation of a homogeneous structure of the tape, which allows creating an inseparable whole cloth. As a result, the area of connection of two parts of the material is not inferior in strength to the other parts of the tape. The only “minus” of hot vulcanization is the duration and laboriousness of the production process, which increases the final cost of the product.

Cold vulcanization is less complicated, and the absence of the need to use special equipment reduces the time of work (approximately by half), reduces labor costs and lowers the cost of the product. The principle of the technology is to connect the laminated edges of the segments with the help of a special glue. At the same time, the stability of the seam is about 70% of the unbreakability of the rubber fabric itself. The application of the method is justified for equipment operating in the thermal range from -45 to +80°С, however, the implementation of the method requires the creation of special conditions, providing for a positive temperature, humidity not lower than the dew point, and the absence of dust.

Mechanical joining of conveyor belts is considered the most efficient method of joining. Unlike vulcanization methods, this technology does not require cutting the edges of the fabric, does not require the use of equipment and the observance of special conditions, being carried out at any temperature, in any degree of humidity and dustiness. Non-detachable mechanical connections are made using bolts or rivets. In those cases when it is necessary to provide a detachable connection, the hinged method is used.